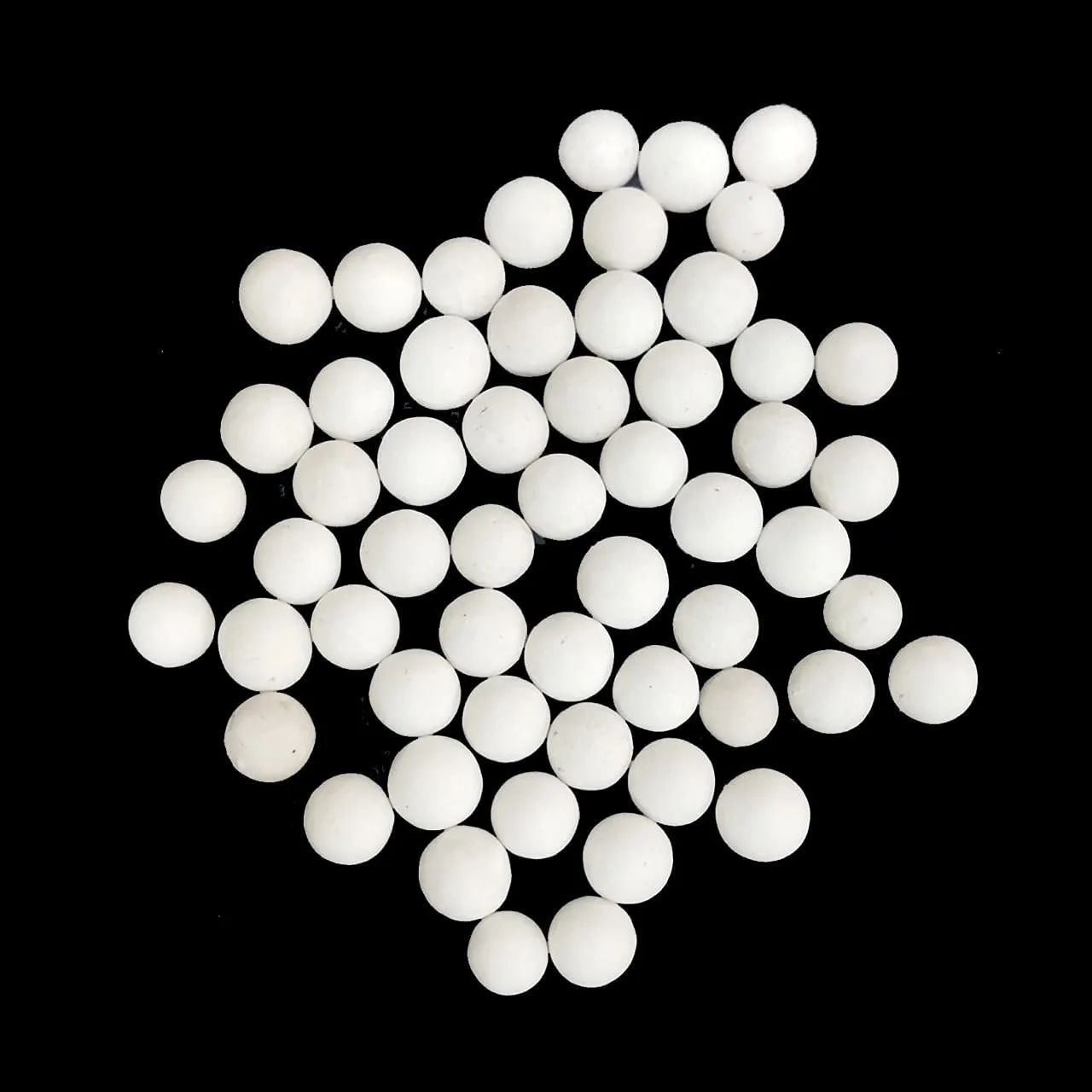

High-Efficiency Zeolite Molecular Sieves for Desiccant & Adsorption Uses

Molecular sieves are a highly porous material that allows for the separation of molecules based on size. Its internal pore volume accounts for 40 to 50% of its total volume, and surface area ranges from 600 to 1000 m2/g (varies depending on grade). Our sieves exhibit exceptional high-temperature resistance, hydrothermal stability, non-flammability, and excellent adsorption performance, making them widely appreciated in separation, adsorption and catalyst environments. As a leading molecular sieves supplier in India, our sieves are available in various configurations, like pellets and beads of different sizes, to help businesses optimize their products & processes while meeting industry & performance standards.